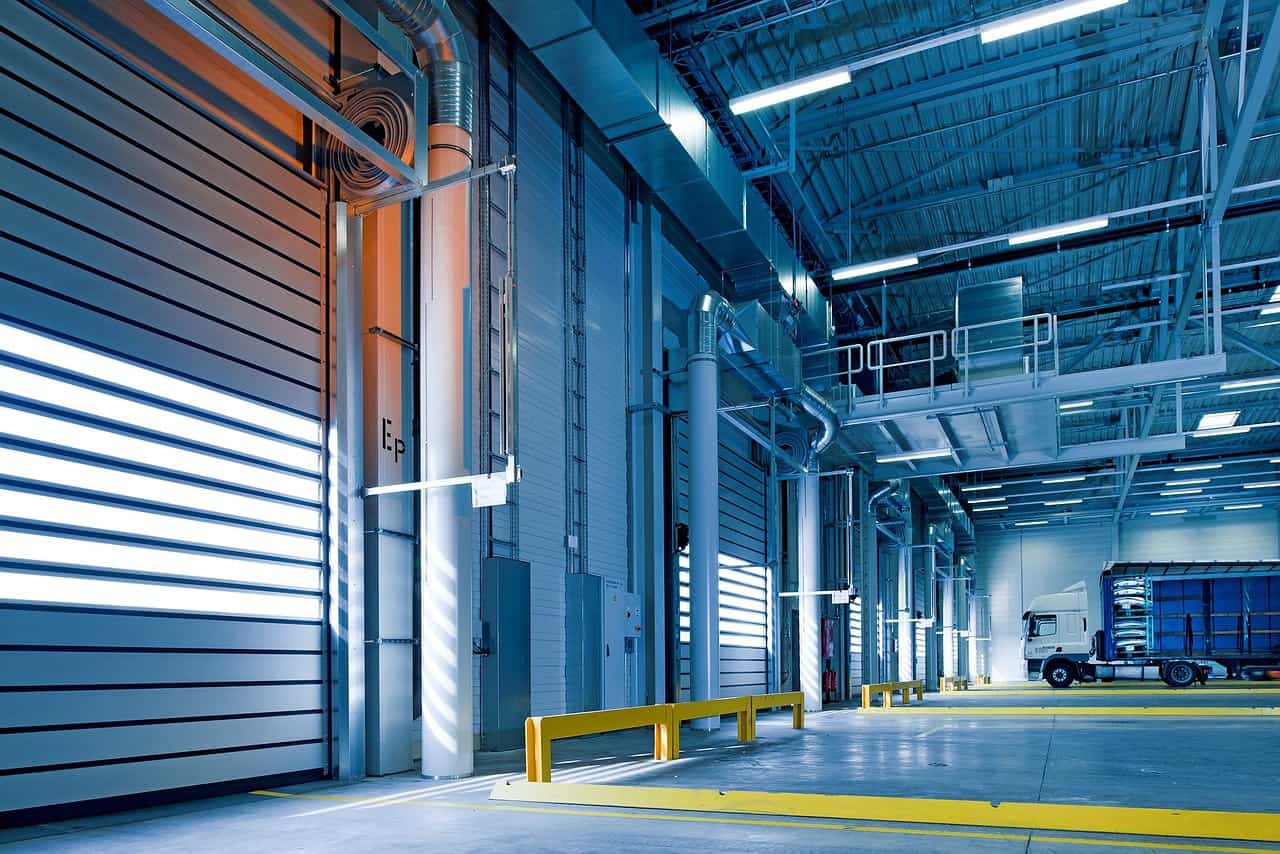

Growing companies are forced to invest in storage – increasing number of orders and sales success means that even the biggest backroom can turn into chaos in no time. The best solution to this problem is to rent or build additional space, which will allow the company to operate efficiently and quickly. What should be in a warehouse?

Supplying equipment for the warehouse before planning the space misses the point. What seems right and necessary to us often turns into unnecessary dustbowls straining your budget – and that can be disastrous, especially for a small, growing business. You should include the following elements in your plan:

It is worth noting that the warehouse plan does not have to be meticulously prepared. Its primary purpose is to provide the best possible functionality and practicality during the daily performance of duties. The beauty is in its simplicity – grab a piece of paper and a pencil and get to work! Make several versions and compare them with each other to make sure you choose the best solution. You can also consult industry literature for useful tips.

Small warehouses are usually equipped with shelving racks with additional storage elements such as baskets or dividers. The solutions available on the market provide surprisingly large usable space and the possibility of proper segregation. What is more, if your warehouse has a high ceiling, it is worth investing in racks corresponding to the size of the room. Specialised ladders will give you access to higher shelves

A combination of both solutions will make your warehouse accommodate a huge number of loads and at the same time release you from the obligation to maintain more space. It is worth noting that bigger is not always better. If your long-term plan includes expanding your warehouse space – consider whether you will definitely not be able to achieve the same goal with less space

There are various types of furniture elements available on the market, which, contrary to appearances, does not make the final choice easier. The most important thing is to be guided by the dimensions of the packages and how they will be stored – i.e. whether you will pack them in boxes, store them loose, and/or whether they have specific requirements in terms of fragility and exposure to the risk of damage to the goods.

As I mentioned earlier, shelving racks are the most common choice for warehouse furniture. The advantage of this solution is versatility, price, and ease of assembly of steel constructions. Shelf racks are used in a variety of industries – from e-commerce, through services, to manufacturing. However, this is not the only type of racking available.

In second place in terms of popularity are racks designed to use the most popular carriers in the transportation world – commonly used in retail. This solution comes with the added cost of handling and managing pallets, which means that only a percentage of small businesses use them.

Regardless of size, every warehouse should have ladders and platforms for easy access to higher-lying goods. Further, small containers and organizers that make it easier to sort smaller goods, as well as storage scales will certainly prove helpful. In addition, the warehouse should also include accessories facilitating the packing process – among others, foil wrappers, which guarantee fast and safe shipment of goods

The above mentioned equipment is only the minimum required in every warehouse. Depending on your business activity, you may be forced to purchase the so-called pallet trucks, containers with specialized use, or coolers. However, this does not change the fact that no warehouse can exist without basic equipment